Design for Manufacture

Project timeline: 4 Months

University Project

Semester: IX

Studio: Design for Manufacture

Faculty: Sadasivan Iyer

Brief

Design for manufacturing is all about creating products that can be produced and assembled efficiently. To get the hang of it, I familiarized myself with the manufacturing process to find ways to maximize production efficiency without compromising on design. The outcome of this project was a factory layout for a mass-produced fire sprinkler. I created manufacturing drawings, a bill of materials, and a manufacturing process while carefully considering which machines to use and where to place them for the most optimized layout.

Standard/quick response

Recessed pendent sprinklers

Recessed Sprinkler is a small, thermosensitive, glass-bulb spray sprinkler available as a standard or quick response type in temperature

This type of Sprinkler comes with an adjustable or non-adjustable escutcheon plate, also known as a rosette plate suitable for installation in false ceilings.

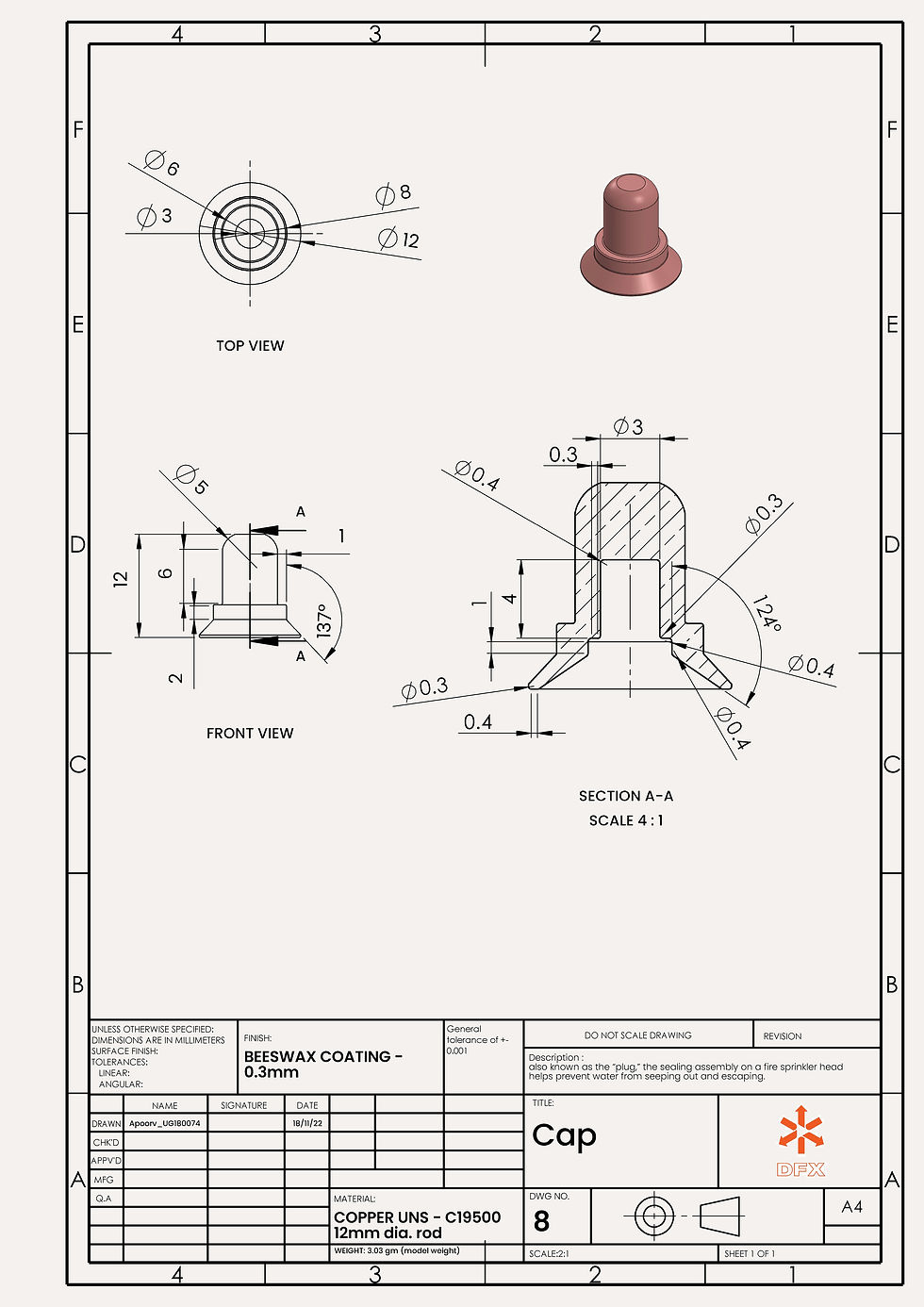

Product design specifications:

Standard/quick response

Recessed pendent sprinklers

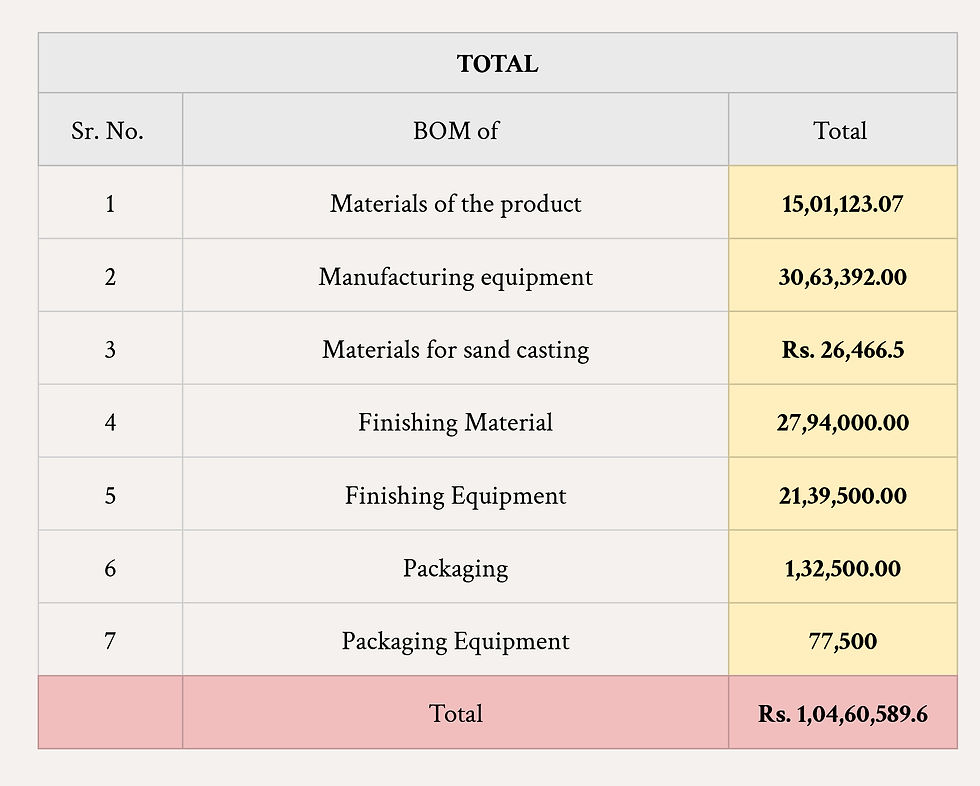

Bill of Material:

A Bill of Materials (BOM) is a critical document that lists all the materials and components required to manufacture a product. It helps to ensure that all necessary parts are available, reducing production time and costs. It also enables accurate cost estimation, assists in inventory management, and improves communication between design and production teams.

Factory Layout:

The following image is a factory layout of a fire sprinkler that involves designing the physical arrangement of machines, workstations, and resources to optimize production efficiency and safety.